Home » All Articles » Calcarenite: Limestone, Sandstone or Coral Stone

Calcarenite: Limestone, Sandstone or Coral Stone

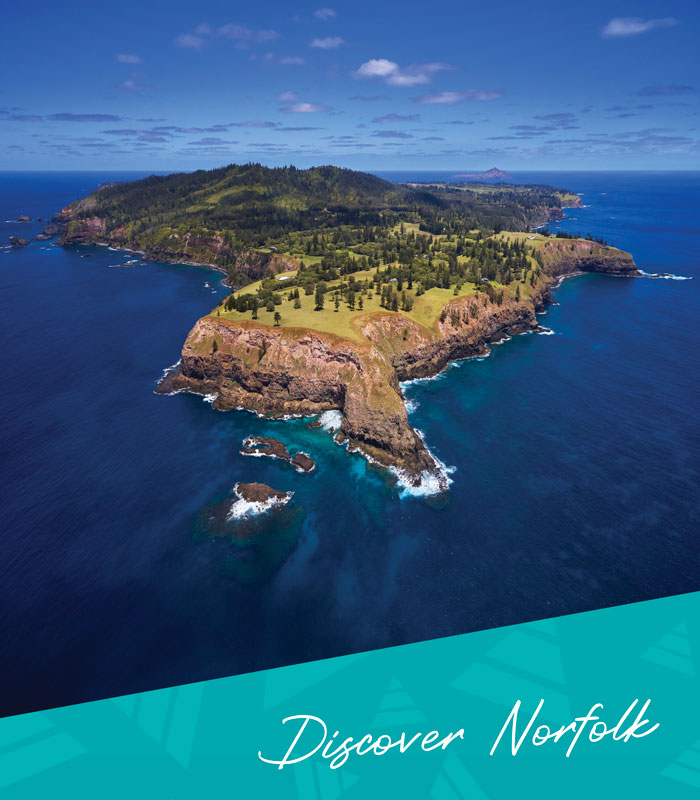

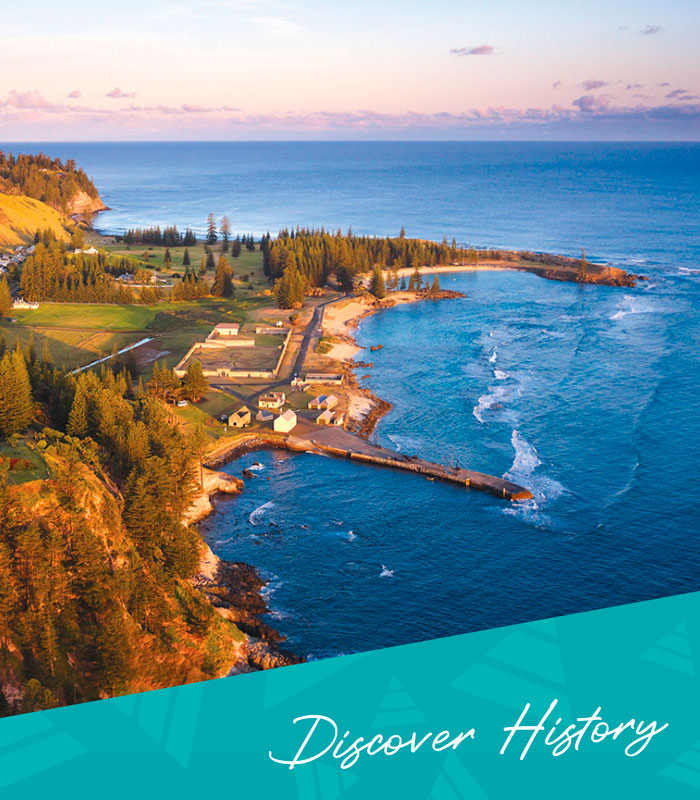

Both Norfolk and Phillip Islands are almost entirely volcanic except the Kingston lowlands and Nepean Island. Following on from the volcanic period, sea levels fell and rose multiple times; extensive reef areas were exposed and eroded. These eroded fragments were blown by the prevailing southerly winds in to the vicinity of Point Hunter (Lone Pine and Setta Point) and Nepean Island. Here they were cemented together to form a sedimentary rock known as calcarenite, probably 120,000 years ago. (ref. Geology of Norfolk Island, Helen Sampson)

Calcarenite is a type of limestone, the carbonate equivalent of sandstone, composed mainly of coral, shells and extinct creatures, compressed over aeons into a solid mass of calcium carbonate, commonly referred to as ‘coral stone’. I’ll refer to it as calcarenite from here on in. The stone ranges in quality and is identified separately as rubble or massive calcarenite – the difference between the two can be attributed to the density of the bedding planes; the rubble being least dense of the two.

The earliest settlers on Norfolk Island were the Polynesians around c. 1300AD; they used this stone. Excavations in the 1990s uncovered hearth stones of rubble and slabs of massive calcarenite formed into a marae.

It was a few years before the First British Settlers recognised the functionality of this stone. Documentation indicates it wasn’t until 1791 when the aeolianitic calcarenite around Emily Bay was recognised as being a form of limestone suitable for building and the manufacture of lime. Chalk and limestone deposits were always sought after since they were a necessary part of any building programme.

It is not surprising that the Emily Bay deposit was not recognised earlier since the settlers, being from Britain, would not have been familiar with limestone in this form; it is a rare occurrence in the British Isles. It would appear that the discovery of this resource was made by accident rather than as a result of scientific investigation.

Good quality lime was produced and a lime mortar could now be made. By 1793 sacks of lime were being sent to Sydney aboard the Kitty. The first experiment was with bricks and mortar, but as the process for making bricks was not successful, the building programmes from 1792 onwards were entirely of wood and stone. (ref. Geology of Norfolk Island, Helen Sampson)

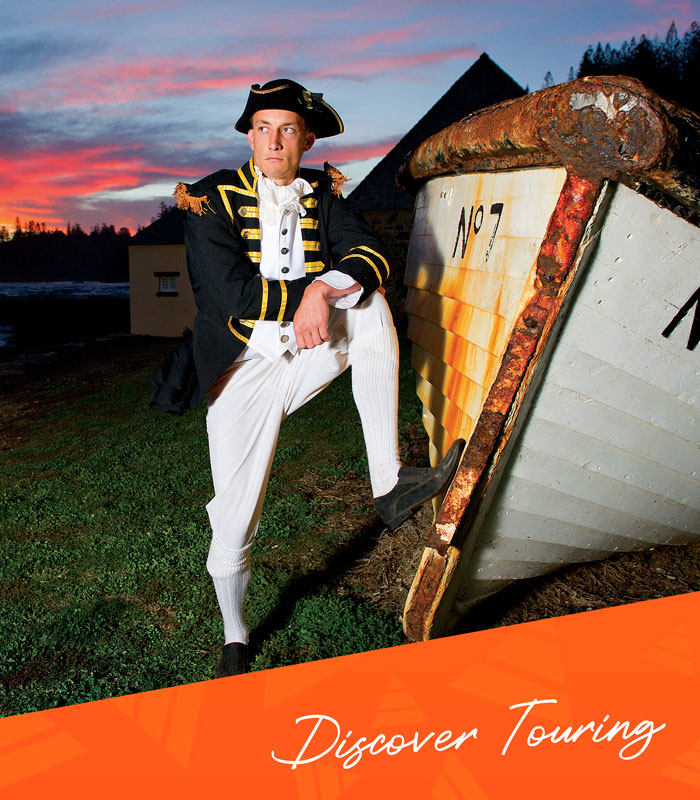

The second British Settlement from 1825 followed with a building programme primarily of calcarenite, leaving for us today a remarkable heritage landscape and fine collection of Georgian buildings. The Pitcairn Islanders took possession of the Kingston buildings upon their arrival in 1856; having no experience in working in stone or burning lime, many buildings began to fall into disrepair. The Governor of NSW sent Mr H J Blinman, a stone-mason and plasterer, to Norfolk Island to develop the skills of the Islanders in this craft. John Adams II, grandson of Bounty Mutineer John Adams, showed particular skill and began attending to the Island’s stone cutting requirements and revitalising the convict lime kilns to manufacture lime. And so began repairs and alterations to the existing structures in the Kingston and Arthurs Vale Historic Area (KAVHA). Restoration and preservation of buildings and structures continues to this day using appropriate and traditional methods to retain the integrity of our built heritage in this area.

Rubble calcarenite was used for roads, water systems, foundations and walls. External walls formed with roughly dressed blocks were jointed together with mortar, also made from this stone, and rendered with a smooth slaked lime-sand mix. Internal walls were rendered with an inch layer of porous mortar, generally mixed with horse hair, and finished with a thin setting-coat of lime and sand. In 1832, it was reported that four hundred convicts on Norfolk Island were shorn to provide the hair for this purpose. Walls were built without any damp-proof measures which led to rising-damp problems.

Mortar was made by burning the stone in a kiln, often built on the side of a hill, to facilitate loading the wood as fuel for the fire. KAVHA still features an intact kiln built in 1845. The quicklime or ‘un-slaked lime’ produced in these kilns was added to water in a pit and soaked for a period of time, thus becoming hydrated or ‘slaked’ and ready for use. The Commissariat Store Museum exhibits a pit, generally thought to have been used for brining, however, we may consider that it was actually a pit for slaking the lime.

The Civil Hospital privy excavation (‘privy’ coming from the Latin word privatus, in this context, it is the toilet) was conducted in 1987 by Dr Robert Varman, Archaeologist and members of the KAVHA works team. Varman reported that ‘layers of lime were intact, remaining in several layers of pure deposit produced by convict labour in one of the three lime kilns on Chimney Hill, near Emily Bay, and dumped into the privy periodically to break down the organic matter and to reduce odours’ (Bairstow & McLaren 1993). Such practice was not new for the period, as the London Board of Health had recommended the use of lime for disinfection in privies as early as 1802’ (Geismar 1993) (ref. Convicting Artefacts, Fiona Starr, 1997).

Visiting English Quaker James Backhouse records his observations of quarrying on Norfolk Island. In 1835, he noted that: ‘Many of the prisoners are employed in quarrying stone and in building a new Commissariat Store. As no gunpowder is used in blasting the rock, and the stone is raised by means of levers, there is a great waste of labour. This is also the case where persons in heavy irons are put to work with those in light ones, or entirely without; the latter having to wait for the tardy movements of the former. Prisoners, generally, are indisposed to industry, and circumstances like these are taken advantage of by them’ (Backhouse, 1843:225).

Further reference to the quarrying of stone by prisoners is obtained from the reminiscences of Major T Bunbury, Commandant of Norfolk Island from February 1839 to September 1839. Bunbury notes that: ‘We had some occupations which were not considered to be so healthy as others; one of these was quarrying up to the waist in water for the manufactory of dripstones to be sent to Sydney for sale’ (Bunbury, 1861:314) (Stanbury & MacLeod: Dripstones).

Skilfully cut massive calcarenite was formed into finishing stones for pediments, sills, chimneys, corners, decorative features and headstones. Floors in the service quarters and the verandas consisted of two inch thick paving-stones laid on a bed of sand. Massive calcarenite is also referred to as ‘dripstone’ – having the necessary qualities for manufacturing a water filtration object, also called a ‘dripstone’.

A dripstone was made by carving, from a block of massive calcarenite, a bowl with a square rim intact, where it may be suspended upon a wooden frame. No written evidence describing the carving of the dripstones from roughly hewn blocks has been found, however Dr Varman’s experiments in making dripstones indicates it would take a considerable amount of time to make one by hand (Stanbury & MacLeod). Water is poured into the carved dripstone bowl; gravity percolates the water through the stone to drip into a waiting vessel below – fresh and clean – it was believed.

The earliest reference to dripstones from Norfolk Island appear in correspondence from the Clerk of the Commissioners in 1831 to the Colonial Secretary: requesting that six filtering stones may be obtained from Norfolk Island to purify the water required for drinking. Dripstones, attributed to Norfolk Island are known to exist in several Sydney locations including the Powerhouse Museum and Elizabeth Farm and many were carried on ships at sea. The 1851 Great Exhibition of spectacular inventions at the Crystal Palace in London featured a Norfolk dripstone.

On Saturday, 25 January 1896 the Sydney Morning Herald featured an interview with Professor Anderson Stuart, President of the Board of Health. He responds to patients suffering from sunstroke, and recommends they refrain from alcoholic beverages of all sorts during hot weather. Instead, he suggests, obtaining good water, then goes on to comment on the dripstone. He stated, ‘You ask me how to get good water, (moaning) a good drinking-water, I presume. That is a matter which has engaged the attention of this department for some time past, and which moreover has been carefully investigated comparatively recently in London, but it was being inquired into here at Sydney even before it was in London, in connection with a very favourite kind of filter in Sydney – I mean the Norfolk Island dripstone, which is a very old-fashioned kind of filter in the neighbourhood of Sydney, and which is very much thought of by the old families in and around this city. But I regret to say that it is like all other ordinary domestic filters – perfectly useless, and even worse. Not so long ago I tested water that had passed through one of these dripstones in the possession of a family in the neighbourhood of Sydney, and for which they had paid no less than £20 sterling. It was a shock to them to learn that the water which had been strained through it was simply swarming with living organisms. Fortunately they were not organisms of disease, but they were organisms – and, after all, one does not pay £20 for a filter to find that the water from it contains “fresh food” in this form’.

Today, the KAVHA site comprises more than forty calcarenite buildings and structures, substantially less than at the closure of the second British settlement in 1855. It is understood the Pitcairn Islanders had no use for gaol cells or prison buildings, nor did they have the skills or capacity to maintain them; the adult male workforce amounted to approximately forty in comparison to a previous convict labour workforce of more than a thousand.

Also, in 1921, the Administrator Lieutenant-General J W Parnell ‘s report recommended – ‘It is desirable to remove many of the old ruins that are standing a foot or two above the ground as they are an eye-sore. There are many of the old ruins and houses quite good enough to repair, and useful buildings can be made from them’. (Parliament of the Commonwealth of Australia, Parliamentary Papers, 1920-21 No.135, p.11)

Parnell’s successor, Administrator Col. Edwin Leane stated that, ‘the aspect of Kingston is most depressing, made up as it is largely of ruins of convict prisons, which have no possible utility, and other buildings, rapidly falling into ruin’ (Parliament of the Commonwealth of Australia, Parliamentary Papers, 1926, No.3, p.11). The Islanders were even encouraged to remove the stone from the second-settlement gaols and associated buildings, and to use it as foundations for their new dwellings as they moved ‘up-country’. A scale of charges was advertised and the monies received were paid to the local Council (Norfolk Island and its Third Settlement, Raymond Nobbs).

The calcarenite buildings are foundational to our rich heritage on Norfolk Island since 1856 and are a significant element of the World Heritage Listed Australian Convict Sites Property.

____

Image Credit: Robin Nisbet

www.robinnisbet.com

____

Article content disclaimer: Article first published in Discover Norfolk, Volume 02 Issue 01, 2018. Please note that details of specific travel, accommodation and touring options may be outdated. References to people, places and businesses, including operating days and times may have changed. References to Government structure and Government businesses/entities may no longer be applicable. Please check directly with businesses and/or Government websites directly rather than relying on any information contained in this article before you make travel arrangements.